ADSS Suspension Cable Assemblies

FEATURES:

1. The suspension clamp has a large contact area with the ADSS optical cable, the stress distribution is uniform, and there is no stress concentration point. At the same time, the rigidity of the optical cable at the hanging point is enhanced to play a better protective role.

2. It has good dynamic stress tolerance and can provide enough grip force to protect ADSS optical cable to run safely under the condition of unbalanced load.

3. The structure is equipped with flexible rubber clamps, which enhances self-damping and reduces wear.

4. The end is rounded to increase the corona inception voltage.

5. The high-quality aluminum alloy material improves the mechanical performance and anti-corrosion performance of the clamp, and greatly prolongs the service life.

描述

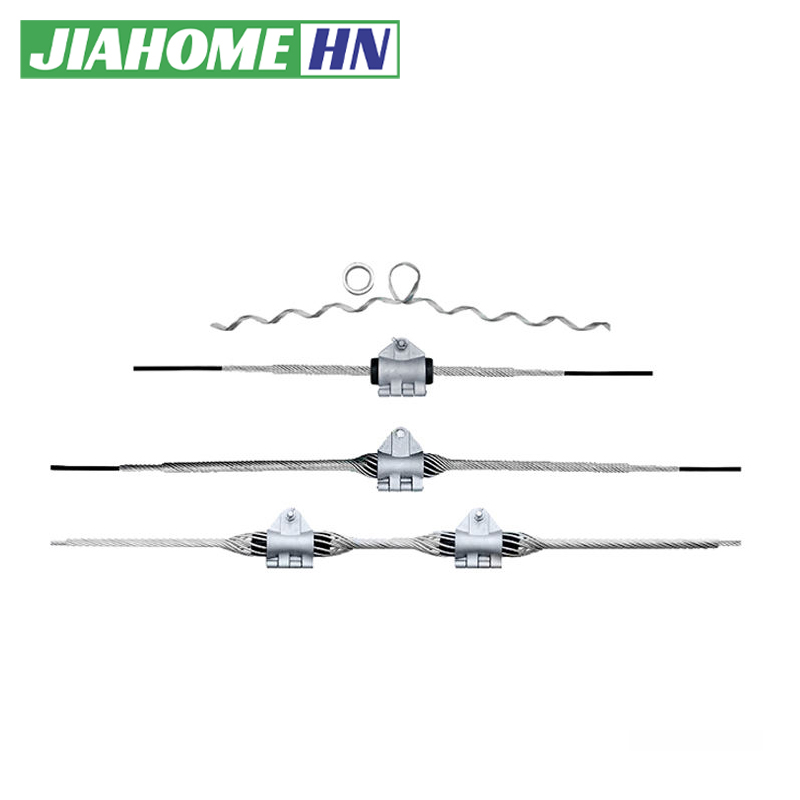

ADSS Suspension Cable Assemblies : Adss optical cable suspension clamp, pre-twisted suspension fittings manufacturers. According to the model and parameter requirements of ADSS optical cable, we can provide suspension clamp fittings with different spans, tensions and outer diameters, which are divided into single-layer stranded wire suspension clamps and double-layer stranded wire suspension clamps.

Single-layer twisted wire suspension clamps are used for actual spans less than 150 meters. Double-layer twisted wire suspension clamps are used for actual spans greater than 200 meters.

Small span suspension clamps accessories include: U-shaped hanging ring, right-angle hanging ring, outer twisted wire, aluminum alloy wire clamp, bolts and other supporting hardware.

Double-layer twisted wire tension clamp accessories include: U-shaped ring, right-angled hanging ring, inner twisted wire, outer Twisted wire, clamps, bolts and other supporting hardware; customers can choose other connection accessories according to engineering design requirements.

Key Components of ADSS Suspension Cable Assemblies:

- Suspension Clamps:

- These are used to attach the ADSS cable to poles or towers. The clamps ensure that the cable is securely held without causing damage to the cable’s sheath.

- Armor Rods:

- Armor rods are used to protect the cable from abrasion and stress at the suspension points. They help distribute the load and prevent bending or kinking of the cable.

- Helical Fittings:

- These are preformed wires that wrap around the cable, providing additional support and protecting against vibrations and dynamic stresses.

- Dead-End Assemblies:

- Dead-end assemblies are used at the termination points of the cable route, where the cable must be anchored securely.

- Thimbles and Shackles:

- These components connect the suspension clamp to the supporting structure, ensuring a stable and flexible connection.

- Vibration Dampers:

- Installed along the cable, these dampers reduce wind-induced vibrations that can cause fatigue and damage over time.

ADSS (All-Dielectric Self-Supporting) suspension cable assemblies are components used in fiber optic networks, particularly for overhead installations where the cable is self-supporting.