Gcyfxty Uni-Tube Air-Blown Micro Cable

FEATURES:

- Perfect cable structure with high fiber density

- Accurate fiber length balance to ensure stable performance

- No gel in cable core for water blocking

- Sheath structure innovation to enhance blowing performance

- Greater blowing distance

- Fiber: G.G652D, G.657A1, G657A2 & multimode fiber

描述

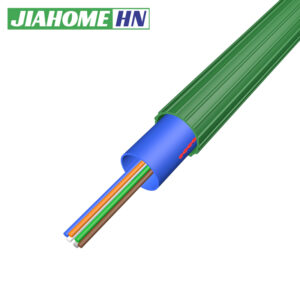

GCYFXTY [Non-metal reinforced member, central beam tube filled type, polyethylene sheathed outdoor optical cable for communication] The structure of the optical cable is that a single-mode or multi-mode fiber sleeved into a high-modulus plastic-filled waterproof compound loose tube. And placed in the center of the cable. Aramid yarn reinforced yarn and extruded polyethylene outer sheath to form the cable.

Technical Characteristics:

| Type | O.D(mm) | Weight(Kg/Km) | Tensile strengthLong/short term(N) | CrushLong/short term(N/100mm) |

| GCYFXTY-2B1.3 | 2.3 | 4 | 0.15G/0.5G | 150/450 |

| GCYFXTY-4B1.3 | 2.3 | 4 | 0.15G/0.5G | 150/450 |

| GCYFXTY-6B1.3 | 2.3 | 4 | 0.15G/0.5G | 150/450 |

| GCYFXTY-8B1.3 | 2.3 | 4 | 0.15G/0.5G | 150/450 |

| GCYFXTY-12B1.3 | 2.3 | 4 | 0.15G/0.5G | 150/450 |

| GCYFXTY-24B1.3 | 2.7 | 6.5 | 0.15G/0.5G | 150/450 |

1. Cable Type:

- GCYFXTY:

- G: Denotes an outdoor optical cable.

- C: Indicates a central strength member.

- Y: Typically signifies a polyethylene (PE) sheath.

- F: Refers to the non-metallic strength member, often made of fiberglass.

- X: Indicates the presence of additional protection, possibly a water-blocking element.

- T: Represents the cable’s armored feature, usually with a tape or a layer that provides extra mechanical protection.

- Y: Again, denotes the type of sheath, usually PE for UV and weather resistance.

2. Core Structure:

- Central Loose Tube:

- The optical fibers are housed in a central loose tube, filled with a water-blocking gel.

- The gel protects the fibers from moisture and mechanical stress.

- Non-metallic Strength Member:

- The central strength member is non-metallic, typically made of fiberglass or aramid yarn.

- This provides the necessary tensile strength while keeping the cable lightweight and non-conductive.

- Armoring (T):

- The cable includes an armoring layer, typically a non-metallic tape.

- This adds mechanical protection against crushing, impacts, and other physical stresses.

- Water-blocking (X):

- Water-blocking materials, such as gel or tape, prevent water ingress and protect the fibers.

- Outer Sheath (Y):

- The outer sheath is made from UV-resistant polyethylene (PE).

- This protects the cable from environmental factors like UV rays, moisture, and temperature fluctuations.

3. Characteristics:

- Non-metallic Design:

- The entire cable is non-metallic, making it safe for use near electrical equipment and in lightning-prone areas.

- Enhanced Mechanical Protection:

- The armoring provides additional strength, making the cable resistant to physical damage.

- Water and Moisture Resistance:

- The cable’s water-blocking materials ensure it remains functional even in wet conditions.

- UV and Weather Resistance:

- The PE sheath protects against UV radiation, weather, and environmental degradation.